Our Story

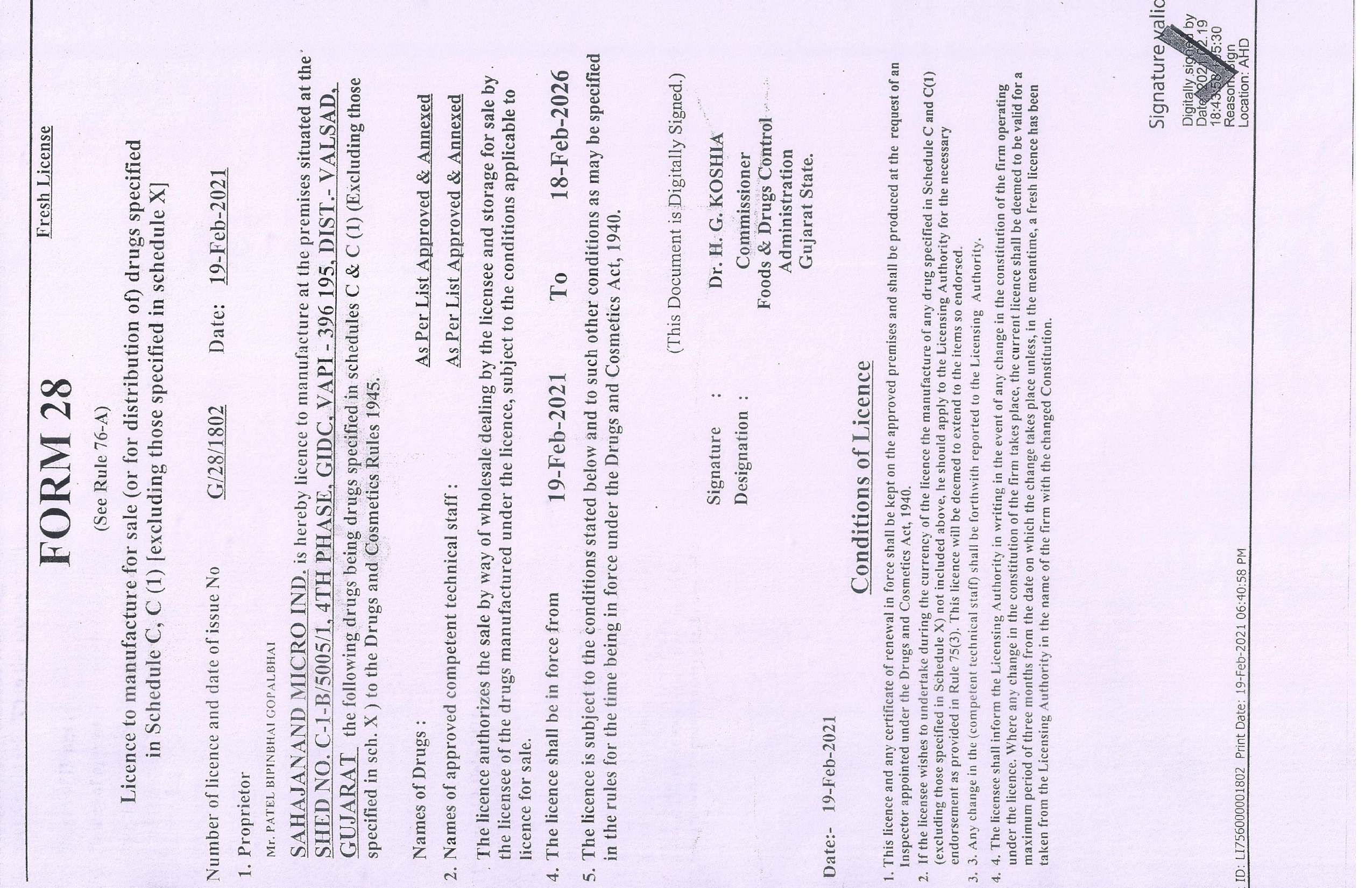

Sahajanand Micro Ind. is an FDA-audited specialist in air-jet micronisation of APIs, bulk drugs and industrial chemicals. From our 3500 sq ft GMP clean-room facility in Vapi, Gujarat—plus a dedicated chemical line capable of 100MT/month in 4500 Sq ft area —we convert coarse feedstock into precisely engineered, contamination-free powders.

With 20+ years of experience, a highly trained technical team and validated cleaning SOPs, we deliver gram-scale trials through multi-tonne campaigns while maintaining tight particle-size distributions, minimal yield losses and zero cross-contamination events.

SAHAJANAND MICRO IND. is a reputable company with a strong presence in the industry. We specialize in providing high-quality filtration solutions to meet the needs of our customers.

Our company is backed by a team of experienced professionals who bring expertise and technical knowledge to deliver superior products and services. We take pride in our state-of-the-art manufacturing facilities, which enable us to produce filtration solutions that adhere to the highest industry standards.

At SAHAJANAND MICRO IND., we prioritize innovation and continuous improvement. We invest in research and development to stay updated with advancements in filtration technology. This allows us to offer cutting-edge products that effectively address the evolving requirements of our customers.

Mission

Our mission is to deliver precise, contamination-free jet-mill micronisation that accelerates drug development and improves patient outcomes, through unwavering quality, technical excellence, and responsive service.

01Vision

Our vision is to be the world’s most trusted, sustainable partner for scalable particle-size reduction, enabling innovators to transform promising molecules into safe, effective medicines faster.

02Core Values

Quality, integrity, innovation, responsiveness and sustainability guide every decision—ensuring audit-ready batches, transparent collaboration, continual process improvement, swift support and responsible operations.

03